Blog

“How TPMS Works: The Technology Behind TPMS”

How TPMS Works: The Technology Behind Tire Pressure Monitoring Systems

In modern cars, the Tire Pressure Monitoring System (TPMS) plays a critical role in ensuring safety, fuel efficiency, and the overall performance of your vehicle. However, many drivers are still unfamiliar with how TPMS works and the technology that powers it. In this article, we’ll explore the inner workings of TPMS, how it monitors tire pressure, and why it’s essential for your car’s safety and maintenance.

What is TPMS?

Before delving into how TPMS works, it’s essential to understand what it is. The Tire Pressure Monitoring System (TPMS) is a safety feature in vehicles that constantly monitors the air pressure inside the tires. If the tire pressure falls below a recommended threshold, the system alerts the driver, usually with a warning light on the dashboard.

TPMS helps ensure that your vehicle’s tires are properly inflated, which is vital for safe driving, fuel efficiency, and tire longevity. The system provides real-time information about tire pressure and allows drivers to take corrective actions before problems escalate.

Types of TPMS: Direct vs. Indirect Systems

There are two primary types of TPMS systems: direct TPMS and indirect TPMS. Both systems monitor tire pressure, but they use different technologies and methods to achieve this.

1. Direct TPMS

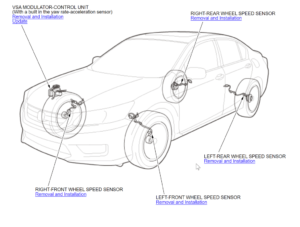

Direct TPMS is the more common and advanced type of system. It uses sensors placed inside each tire (usually attached to the valve stem) to directly measure the tire’s air pressure. These sensors continuously monitor the pressure and send the data to the car’s on-board computer system.

The key features of direct TPMS include:

- Individual tire monitoring: Direct TPMS provides real-time, individual readings for each tire, allowing you to know exactly which tire is underinflated.

- Sensor technology: The sensors inside the tires communicate wirelessly with the vehicle’s central system, sending alerts when the pressure drops below a certain level (typically 25% below the recommended pressure).

2. Indirect TPMS

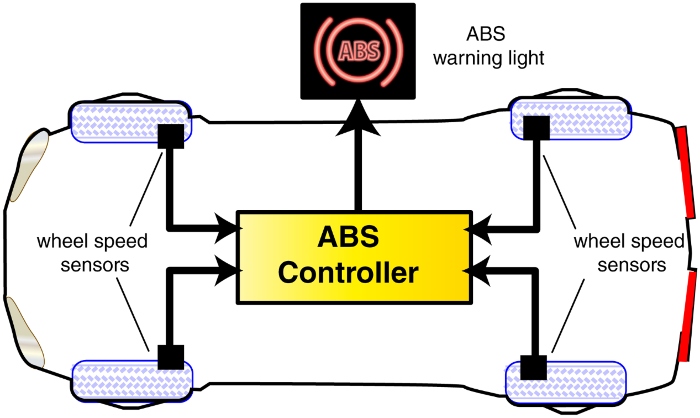

Indirect TPMS, while still a valuable safety feature, does not use sensors inside the tires. Instead, it relies on the vehicle’s ABS (Anti-lock Braking System) and wheel speed sensors. These sensors detect any differences in the speed of rotation between the tires.

The basic idea is that when one tire is underinflated, it will have a smaller diameter and will rotate faster than a fully inflated tire. The system notices this discrepancy and alerts the driver that there may be an issue with one or more tires.

While indirect TPMS is less precise than direct systems, it still serves as an early warning system for tire issues. However, indirect TPMS may not be as accurate in monitoring individual tire pressures, and its effectiveness can be impacted by factors such as tire wear or road conditions.

How Direct TPMS Works: Step-by-Step Process

Now that we’ve covered the two types of TPMS, let’s focus on the more widely used direct TPMS. Here’s a step-by-step breakdown of how this system works:

1. Tire Pressure Monitoring

The direct TPMS sensors are installed inside each tire, typically attached to the valve stem. These sensors continuously monitor the air pressure within the tire and measure it against the manufacturer’s recommended levels.

2. Wireless Communication

Once the sensors gather the tire pressure data, they wirelessly transmit this information to the vehicle’s on-board computer. The data includes the pressure level for each tire, which is continuously updated.

3. Alert Mechanism

If any tire’s pressure falls below the recommended level (usually by 25% or more), the system triggers a warning light on the dashboard. This alert can take the form of a yellow exclamation point or a tire-shaped icon, depending on the vehicle manufacturer.

In some cases, the system may also provide additional information, such as the specific tire that’s underinflated, so the driver can take immediate action.

4. Driver Action

Once the driver receives the alert, they can take steps to resolve the issue. This typically involves stopping the vehicle in a safe location and checking the tire pressure with a gauge. If necessary, the driver can inflate the tire to the proper pressure or seek professional help if the issue persists.

Benefits of Direct TPMS

There are several benefits to having a direct TPMS in your vehicle, including:

1. Improved Safety

By monitoring tire pressure in real-time and alerting the driver when it falls below the safe threshold, direct TPMS reduces the risk of tire blowouts or accidents caused by underinflated tires. Underinflated tires are more prone to overheating, which can lead to tire failure. With TPMS, you can address tire pressure issues before they become dangerous.

2. Better Fuel Efficiency

Properly inflated tires are crucial for maximizing fuel efficiency. When tires are underinflated, they create more rolling resistance, which forces the engine to work harder. This leads to higher fuel consumption. By ensuring your tires are always at the optimal pressure, TPMS helps improve fuel economy and reduce your carbon footprint.

3. Longer Tire Life

Tires that are consistently under or overinflated wear out unevenly, leading to the need for early replacement. By maintaining the correct tire pressure, TPMS helps extend the life of your tires, saving you money on replacements and improving overall vehicle performance.

4. Enhanced Vehicle Handling

Proper tire pressure is key to ensuring the best handling and stability of your vehicle. Whether you’re navigating tight turns or driving on slippery roads, having the right tire pressure ensures that your tires perform optimally, providing better traction and control.

Common TPMS Issues and Troubleshooting

Although TPMS is a highly reliable system, there are a few common issues that drivers may encounter:

1. TPMS Warning Light Stays On

If the TPMS light stays on after inflating the tires, it could indicate a malfunction in the system, such as a faulty sensor or a communication issue between the sensor and the vehicle’s computer. In this case, it’s best to have the system inspected by a professional.

2. Low Battery in TPMS Sensors

The sensors inside the tires run on batteries, which have a finite lifespan (usually 5-10 years). If the battery in one or more of the sensors runs low, the system may fail to detect tire pressure, and the warning light will appear.

3. Tire Pressure Issues

Sometimes, the TPMS light may come on even if the tires are properly inflated. This could be due to temperature changes, where tire pressure naturally fluctuates. It’s essential to check your tire pressure manually and ensure it aligns with the recommended levels.

Conclusion

TPMS is a vital technology that enhances the safety, efficiency, and performance of your vehicle. Whether you have a direct or indirect TPMS system, both are designed to ensure that your tires are properly inflated, reducing the risk of accidents, improving fuel efficiency, and extending tire life. If you notice any issues with your TPMS, it’s essential to address them promptly to maintain the system’s reliability.

By understanding how TPMS works and maintaining proper tire pressure, you can enjoy a safer, more efficient driving experience.